Redline Technology

Certified safe for drinking water, Redline is most commonly utilised to coat water systems. Redline has many other applications including, fire suppression systems, chiller and heating lines. The process prevents future leaks while it protects you from lead and other and other contaminates leached from your piping into your water.

As a non-invasive pipe rehabilitation process, Redline can be used not only as a long-term solution to prevent corrosion and pin-hole leaks, but as a preventative tool to preserve the life of existing piping systems.

Redline is suitable for use in host pipes which are designed to hold pressure, from hot and cold drinking water lines to air and water systems, heating and cooling lines. Redline is designed to rehabilitate pipes consisting of materials including metal, iron and steel. We can Redline 1 to 1000 metres.

Flowwise is proud to offer Redline as a potable pipe lining technology. This simple but highly effective cured in-place pipe restoration system completely coats the inside of your copper or galvanised pipe. The process prevents future leaks and protects your water from lead and other contaminates leached from your piping.

Pipes with a nominal bore reduced to as little as 20 per cent, can be cleaned back out to nearly its full potential, then coated to reinstate its integrity, extending the life of your asset exponentially.

Redline has been used successfully in a variety of applications including hospitals, high rise apartments, factories, fire suppression systems and domestic homes.

What are the benefits?

- safe and durable

- cost effective

- minimal downtime compared to re-piping

- minimal disruption and no occupant displacement

- versatility in applications

- prevents future pin hole leaks and corrosion.

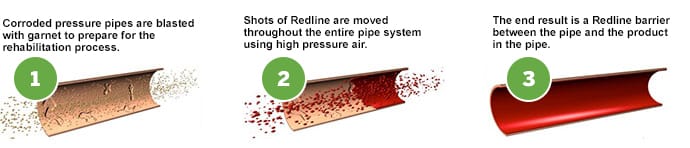

How does the Redline process work?

Once this has been completed, epoxy is blown into cleaned pipes, forming a safe, evenly coated permanent barrier between pipe walls and the product in the pipe. This prevents future corrosion and pinhole leaks forming.

The cause of your pressure pipe problem is identified through water pressure tests and water flow tests. Once this is completed the pipe system is traced.

On completion the pipes are again pressure tested to ensure the problem has been solved.

Specifications

- pipe diameter ranges from 1/2 inch to 10 inches, with larger custom sizes available

- in pressurised pipe systems, the epoxy lining withstands the psi rate of the host pipe

- will tolerate and negotiate multiple 45 and 90 degree bends.

What our customers are saying

Contact us today for a FREE quote!